PET FOOD NEWS

| Looking for economical pet food packaging?We can offer you a rather different, cost-effective packaging solution!We have THE packaging solution for wet food that will save you cash: clip-pak® – packaging in a tubular package with clip closure. This is the most reasonably-priced, visually appealing packaging for pet food, allowing products in both small and large batch sizes to be packaged in sausage form at low cost. | |

| | ||

| A range of packaging films Package your wet food in heat-sealable laminated film (plastic or aluminium laminate) or in plastic casings: deep-frozen products, fresh food, hot filled, pasteurised products or sterilised products. Regardless of whether you’re a small producer or a large international company. Trust in our experience and our packaging solutions – trust in Poly-clip System. | |

| | ||

| Up to 30 % cheaper Bring a reasonably-priced, attractive product onto the market. Compared with tins or trays, the packaging costs for tubular packages are approximatly 30 % less expensive and the packaging waste for consumers is reduced to a minimum. Packaging in small film rolls or plastic casings to form sausage-shaped products reduces, or completely dispenses with, pre-fabrication or large-scale storage of tins or trays. On a cost comparison, clip-pak® offers clear advantages over tins, since tin fillers and closers require a considerable volume of investment. The costs of a filling line for clip-pak® are by comparison substantially lower, and so their use is extremely cost-effective. | |

| | ||

| Contact

Are you interested in this profitable packaging solution? Our specialist, Mr Lars Scheerer, is looking forward to answering your questions relating to the packaging solution clip-pak®. Phone: +49 6190 8886-461 | |

| | ||

| Ideal for pet food Pet food packaging in clip-pak® (also known as ‘dog sausages’) is only suitable for wet food, which is filled into heat-sealable laminated film or plastic casings. This is comparable to products that are filled into tins or trays, for example. There are a variety of package weights corresponding to differing dog sizes, and in addition a wide range of pet food presentations in clip-pak® corresponding to the differing needs of pet owners. These include deep-frozen products, fresh food, pasteurised products as well as sterilised products. | |

| | ||

| Fresh food and long shelf-life Sterilised products packaged in clip-pak® are the alternative to wet products in tins and trays. Pasteurised products offer pet owners a fresh, ready-prepared product that already contains additives such as rice, fish, chicken, vitamins etc. With appropriate cooling, they can be kept up to 3 months. Fresh food can be kept for one week at most, at temperatures of 4 to 8°C. Deep-frozen products have a longer shelf life of up to six months in frozen condition. | |

| | ||

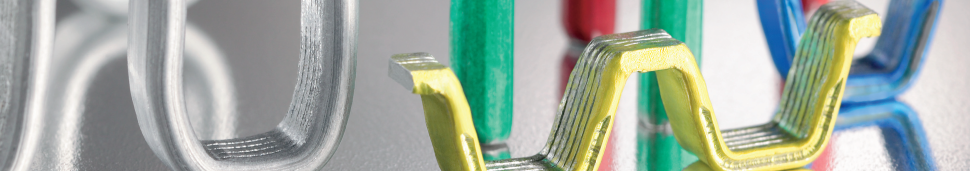

| Contamination excluded Further thermal processing ensuring a longer shelf-life for wet food occurs within the closed packaging. This excludes the possibility of contamination from outside. Thanks to the 30 % higher closing force provided by our R-ID Clip, clip closure also makes the products suitable for further thermal processing in the autoclave. The R-ID Clip guarantees a higher degree of tightness which, in conjunction with the correct packaging material, extends to bacteria tightness. | |

| | ||

| How is it done? And with what? clip-pak® packaging for pet foods is of interest to pet food manufacturing companies of widely varying size. Considerable cost benefits are achievable with a production line based on a sealing/clipping unit linked to an appropriate pump. With an automatic sealing/clipping machine, e.g. the TSCA 160/120 from Poly-clip System, all sealable films can be cost-effectively processed. The film is formed into a tube, sealed and then transported to the clipping unit ready for filling. After ejection of a portion by the filling machine, the end of the one portion and the beginning of the next are simultaneously closed by the so-called double-clipping process. There are up to 3,000 m film available per roll, providing for continuous production. Easy change of packaging size is possible with just a few handgrips, no tools required. Depending on the size of the company and the production volume, manual clipping machines, such as the DCD or PDC from Poly-clip System, may also be used. With medium and larger production volumes, automatic machines in the FCA series are also used, which employ shirred plastic casings. | |

| | ||

| | ||