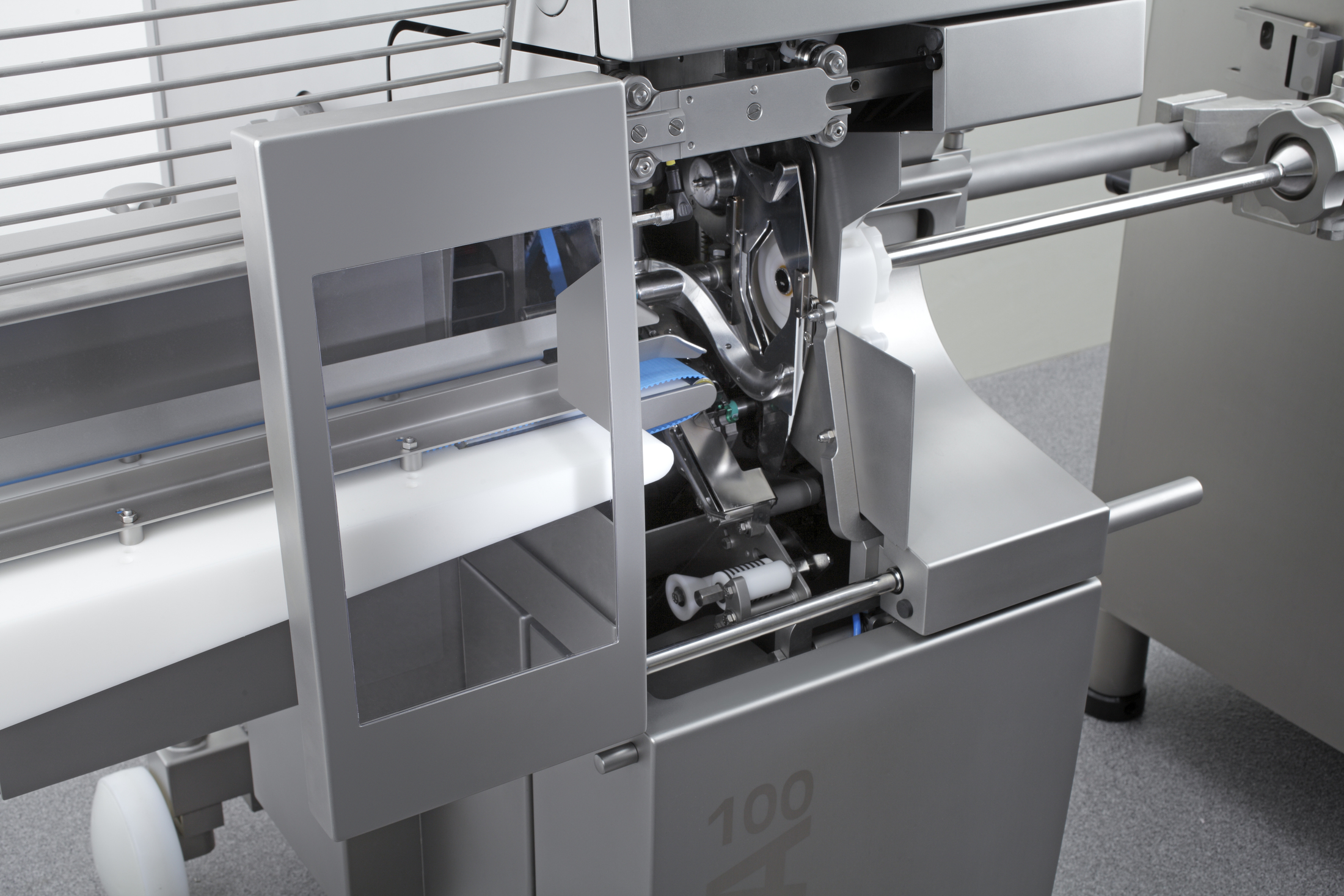

Обещание качества от Poly-clip System

Наши машины, расходные материалы и сервисное обслуживание отвечают самым высоким требованиям. Об этом говорят не только многочисленные сертификаты, но и прежде всего наше собственное стремление к совершенству - Excellence in Clipping. Тем самым мы гарантируем вам надежность и безопасность, которые вы ожидаете для своего производства. Запасные части мы поставляем по всему миру в кратчайшие сроки, быстрым и удобным способом. При необходимости наша техническая служба скорейшим образом прибудет на место.