World market leader

Our customers have made Poly-clip System the world's leading manufacturer of clip closure solutions because they trust in our Excellence in Clipping.

Pioneering achievement led to international success

Even during the development of the reel clip (R-clip), Herbert Niedecker, son of the company founder, had his sights firmly set on customer benefit. He wanted to ensure the secure and fast closure of sausages and similar products. This is a promise he has stuck to, and in the process, he is revolutionising the global manufacture of sausage-based goods.

Our next development was another pioneering endeavour: a new machine enabled the ends of the sausages to be cleanly cleared out using a voiding separator, while at the same time sealing up the start and end of the sausage. We invented the double-clip method – thus shaping industrial sausage production as we know it today.

We are of course proud of these inventions, however, we are not resting on our laurels. For we are always discovering new ways to proactively tackle the challenges our customers are facing. From the once simple clip, to a highly precise, tamper-proof closure, which even produces a seal that is impervious to bacteria.

Sophisticated technology for a variety of sectors

There are numerous different factors that affect the sealing process, such as temperature, type of content, material and characteristics of the packaging sleeve – to name but a few. As a technological leader, we are able to precisely coordinate these factors, and make the clip fastening method attractive for various industries. After all, clipping represents an efficient, cost-effective and sustainable packaging method for the chemicals, pharmaceutical and even the explosives industry.

We can honestly say that there is probably no other manufacturer that understands you as well as we do.

Our customers can always rely on our innovative capacity.

Increasing customer benefit through relevant innovations

You can rely on our innovative capacity at all times. Our development teams maintain close customer contact, as a result of which suggestions that arise during practical operations frequently lead to needs-based solutions, optimisations and even pioneering new developments. As a result of this, we currently hold more than 800 patents, which - each in their own individual right - have transformed the packaging industry.

In this regard, our technological leadership is always striving to optimise our customers' ability to compete and their future sustainability.

We therefore invest a great deal in research and development, with a view to offering you cutting edge technology - often tomorrow's technology today. Consequently, more than 8% of our annual budget flows into laying foundations and further developments.

In brief: targeted innovations, top quality and unparalleled reliability, in combination with an exceptional service – as a global market leader based right on your doorstep, this is precisely what we offer you.

We now generate almost 90% of our turnover outside of Germany. And our brand is represented by a network of exclusive distribution partners in over 145 countries and is represented every year at more than 50 exhibitions.

Our strengths, at a glance

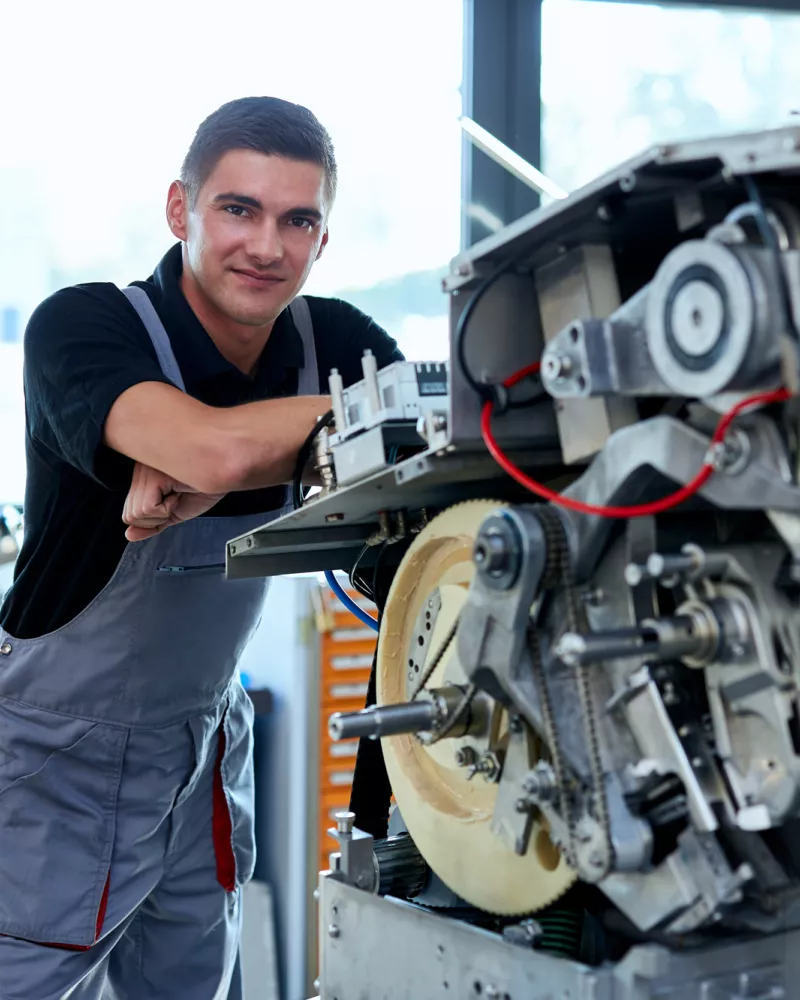

World-beating service competence

When it comes to service competence, we set the benchmark within this sector. And while this remains true on a global scale, we are nonetheless always close by and on hand to assist you.

The result: Anywhere sausages are produced, anywhere sustainable packaging systems are required... people know us. As such, nowadays FCA and ICA double clipping machines (sausage clippers) from Poly-Clip System are used in almost every meat processing business.

For the most diverse of reasons, our global customer base intentionally rely on our clipping machines, whether manual, semi-automatic, or fully automatic. What they all have in common is a shared realisation: our products and solutions are synonymous with successful and continual streamlining, and not just in the area of sausage production.

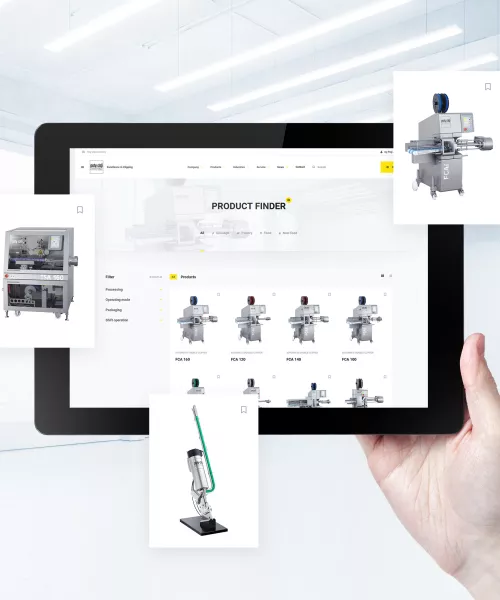

Product range tailored to your requirements

Our range of products and services covers a wide variety of innovative solutions, including clipping machines, packaging machines and their automation, as well as consumables such as clips and loops.

Our portfolio is supplemented by a wide range of one-off services for our customers. Whether fault correction, maintenance, the provision of spare parts, application consultation, or training courses – all of these services aim to ensure that our customers around the world achieve the highest possible level of safety, productivity and profitability. And always just in time.

Clip fastening solutions for almost every industry

We supply the food industry around the world, primarily industrial producers and the butchery trade. Packaging with a clip is also a secure and hygienic way to package poultry and poultry cuts in bags. The packaging system with the clip closure is efficient, cost-effective, and sustainable. However, our clip fastening system has also enjoyed success in other industries that process and pack products in paste form, both in the foods industry and within the non-food sector. Further important markets are dairy products, convenience products, bakery products and confectionery, pet foods, sealants and adhesives and civilian explosives.

Safe for use with foods

The safety of consumers, that is to say your customers, is our primary concern. Worldwide, we are the only company in the area of clip closure technology that has certification of our consumables carried out by the SGS INSTITUT FRESENIUS and has been awarded their quality seal. Central to this certification is the testing of products to ensure that they are safe for use with foods (SAFE-COAT, ISO 22000). The test criteria for this go far beyond any legally prescribed measures.