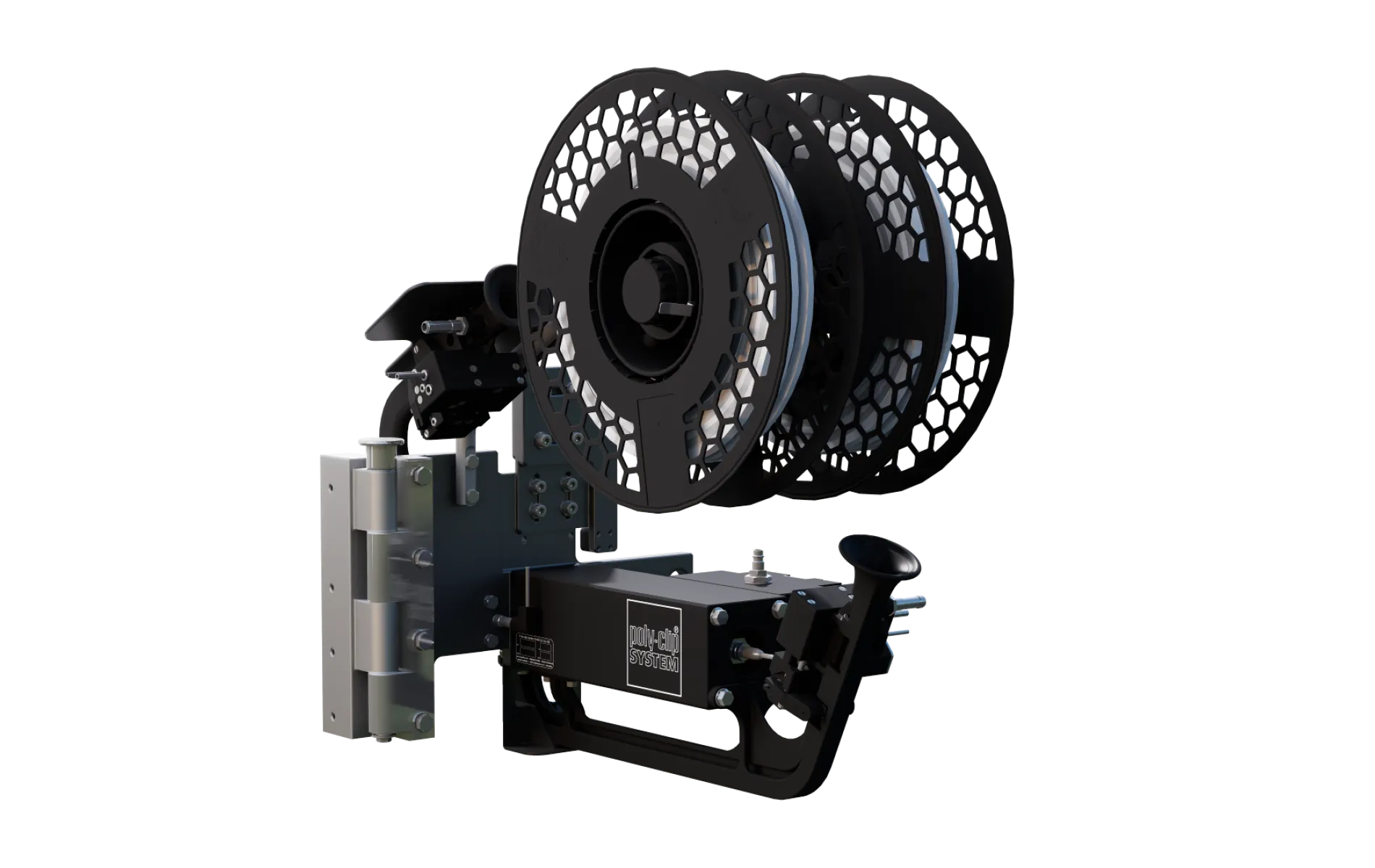

Automatic Casing Loading (ADNL) – A revolution in sausage production

With its Automatic Casing Loading (ADNL), Poly-clip System takes efficiency in sausage production to the next level. Developed for models FCA 120, 160 and 160 XL, the ADNL enables continuous casing reloading, ensuring almost uninterrupted production processes. Thanks to automatic removal of residual casing and end detection, manual intervention is reduced to a minimum. The system eliminates the need for constant operator presence at the reloading station. At the heart of the machine is a sophisticated magazine system with automated casing change, ensuring smooth operation. This allows for up to two hours of uninterrupted production without any operator input. It relieves staff, saves valuable time, and enables the supervision of multiple lines in parallel – a clear step towards the “Smart Factory”. Manufacturers benefit from consistent productivity, increased equipment availability and reduced labour costs.

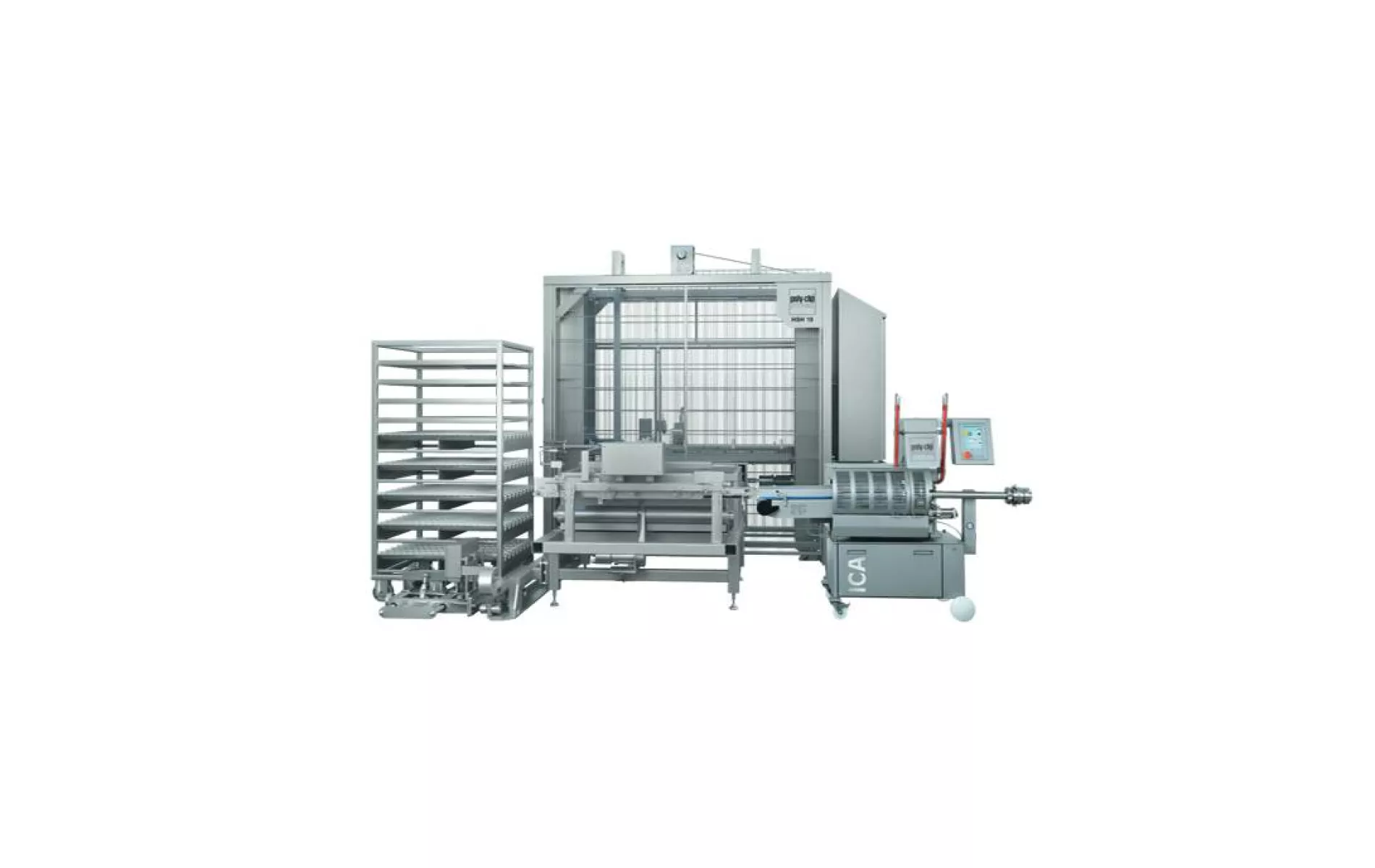

HSH 18 – Automated loading of smoke trolleys with heavy sausages

At IFFA, Poly-clip System presents the HSH 18 (Heavy Sausage Handling), an innovative solution for fully automated horizontal loading of smoke trolleys with heavy sausages. The HSH 18 can be positioned downstream of automatic double clippers from the ICA or FCA series. It reliably processes sausages with diameters from 80 to 250 mm, lengths up to 1,200 mm and weights of up to 18 kg. A camera-based measuring system identifies various smoke trolleys and loads them with precision. Sausages are placed into the trolley via a linear conveyor system and a cam-controlled loading fork. An integrated buffer belt ensures continuous product flow even during trolley changeovers. The HSH 18 not only significantly reduces the physical strain on operators, but also increases production safety and efficiency. “The HSH 18 recognises different types of smoke trolleys, including those already in use at customer facilities. With this development, we’ve taken into account the real-world production conditions of our customers, who won’t need to invest in new trolleys for this automation step,” explains Dr. Alexander Giehl, CEO at Poly-clip System.

Poly-LogBot® – Intelligent transport robot for seamless automation

Under the name “Poly-LogBot® powered by Sherpa”, Poly-clip System presents a world first at IFFA 2025: the first splash-resistant transport robot specifically designed for the food industry.The Poly-LogBot® fully automatically connects two production stations. It is easily integrated into production workflows, for example to pick up, transport and swap crates. It meets the highest hygiene standards and operates reliably even under demanding conditions, such as in wet areas. This smart robot combines intelligent robotics with food-grade engineering and will be demonstrated live at the trade fair.

FCHM-MB – Efficient clipping, loop application and precise hanging in one system

Another trade fair highlight from Poly-clip System is the FCHM-MB – a compact, cost-efficient all-in-one solution for automatic clipping, loop application and precise hanging. Designed especially for medium and small production volumes, it combines three process steps in one system – without the need for additional machines such as a double clipper. It impresses with easy operation, precise loop control and flexible recipe management. Its robust stainless steel construction in hygienic design enables easy cleaning, making it ideal for modern production environments. “The FCHM-MB achieves up to 40 loops per minute for smaller product diameters of 35 to 65 mm and reduces personnel requirements by up to 20 per cent. It meets our customers’ highest expectations for efficiency and cost-effectiveness,” says Dr. Alexander Giehl.

Press contact

Poly-clip System GmbH & Co. KG

Niedeckerstraße 1

65795 Hattersheim a. M.

Deutschland