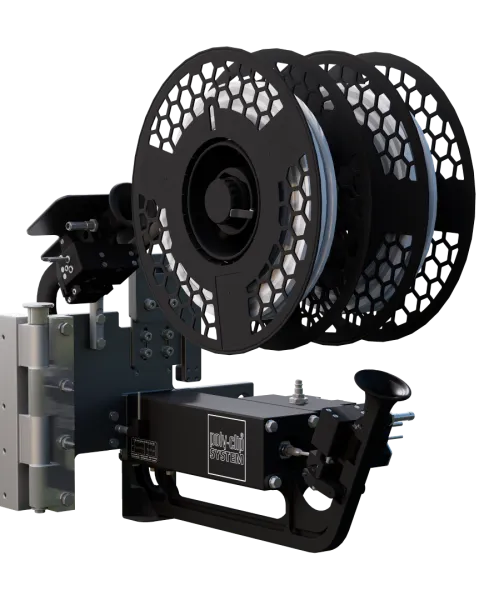

SCH - proven single clipper for the trade: now even more powerful

The SCH, one of the best-selling single clippers in Small-scale businesses, has been completely redesigned and now shines in new light. The latest model impresses with an even slimmer design, which makes it easier to transport and noticeably improves handling, resulting in an attractive price-performance ratio. New features include innovative components from the 3D printer, which not only reduce the weight but also significantly minimise the effort required to close cuts, portions and pouches. The result: more efficiency, less fatigue - ideal for the demanding daily operations in retail. Thanks to its high flexibility, the SCH effortlessly processes all plastic, fibre, collagen and natural casings up to a calibre of 90 mm. Operators benefit from an adjustable clip pressure and easy handling, which enables use even under changing conditions. The new version of the SCH remains the ideal tool for artisan businesses that rely on maximum flexibility and efficiency when processing sausage and meat products. New features such as the 3D-printed components and the optimised design make the machine even more robust and user-friendly.

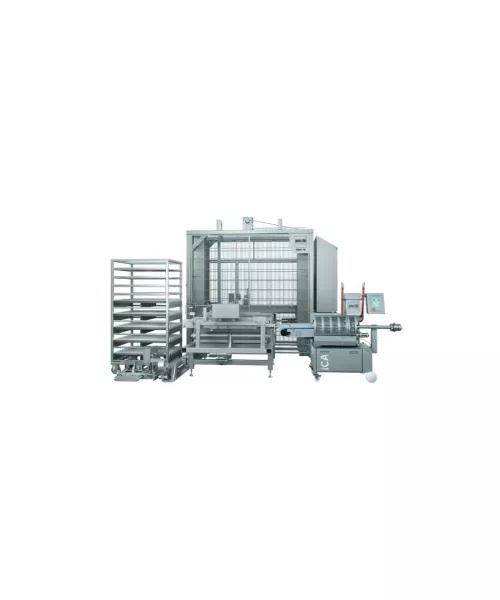

Enhanced APL for Poultry Packaging: More Efficient, Reliable, and Flexible

At IFFA 2025, Poly-clip System will present the new version of the APL – an automatic packaging machine for poultry processing. Now equipped with new features, it makes the entire packaging process even more efficient, reliable, and user-friendly. One highlight is the newly designed sword guide in the insertion area, which simplifies the loading of poultry, regardless of the condition of the skin. The moulded parts have also been further optimised to accommodate different chicken sizes. Products are now guided with even greater precision, ensuring improved fit and higher process reliability. In addition, the new APL features an innovative bag inflation station, where the packaging bag is inflated from above using a nozzle. This ensures even more precise control and prevents the bags from being torn or incorrectly filled. The APL can optionally be supplemented with an inline printer – ideal for companies that value consistent labeling and traceability. Another option is the integration of a labeller, including label printing.

Press contact

Poly-clip System GmbH & Co. KG

Niedeckerstraße 1

65795 Hattersheim a. M.

Deutschland