Innovation by Tradition

For over 100 years, Poly-clip System has stood for precision, ingenuity, and technological excellence. As a pioneer of in clip sealing technology, the company from Hattersheim has shaped the industry and continually redefined its standards. Today, Poly-clip System is far more than the inventor of classical clipping: the heritage-rich company has evolved into a integrated packaging company – offering a perfectly coordinated system of machines, matching consumables, and smart automation. With innovative solutions across the entire value chain, Poly-clip System sets new benchmarks for efficiency, sustainability, and flexibility in packaging technology. Whether sausages, alternative proteins, or non-food products: cutting-edge manufacturing technologies enable tailored, resource-efficient packaging solutions for a wide range of industries and demands. Companies of all sizes find the right solution in the Poly-clip System portfolio – from hand clippers and compact machines to fully automated production lines. The system evolves with its customers, their needs – and the demands of tomorrow..

Automation and AI to Tackle Skilled Labor Shortages and Rising Costs

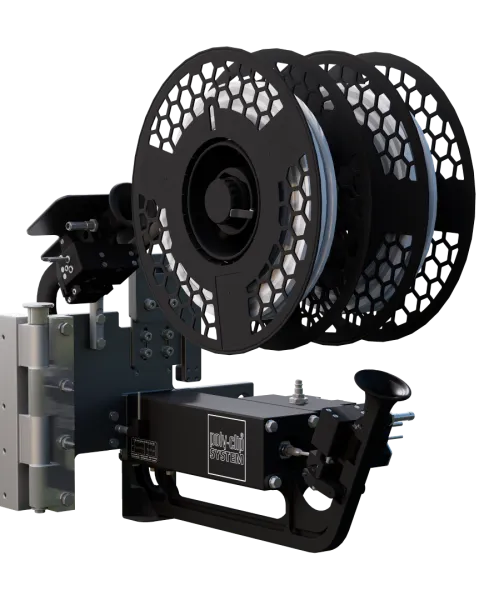

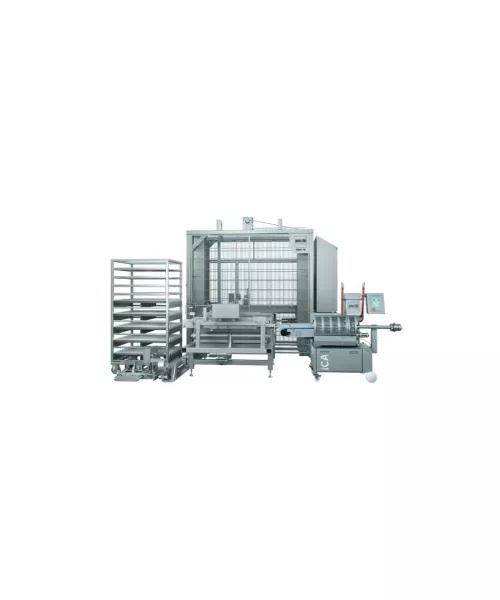

The meat processing industry is under pressure: According to statistics[1], 86 per cent of companies report difficulties in finding qualified staff. At the same time, energy and labor costs continue to rise. Poly-clip System is addressing these challenges with advanced automation solutions. One of the trade show highlights is the new technology for automatic casing reloading (ADNL) – a real game-changer in terms of efficiency and workplace safety. The integration of the new transport robot (Poly-LogBot®) also eases daily production tasks: It takes over heavy lifting operations and intelligently connects different production stations. Another milestone is the AI-driven loading process. Machines now handle the automatic loading of smoke trolleys, detect defects more reliably, and help prevent product issues such as burst sausages.

Smart Glasses Revolutionise Service

Another trade show highlight under the heading of “digitalisation” is the use of smart glasses, the PVA (Poly-clip System Virtual Assistant), in technical service support. With these smart glasses designed for customers’ in-house technicians, Poly-clip System experts can provide real-time remote assistance. Connected via WLAN or 4G/5G, the Poly-clip experts look at the machine together with the technicians on site. Technical details and instructions can be digitally displayed directly into the technician’s field of view. The benefits of Smart Glasses are clear: technical issues can be resolved more quickly, machine downtime is reduced, and travel costs are minimised. The solution, based on specialised hardware and the PCS VIA app, is modular and scalable.

Strategic change with vision, focus on sustainability

Poly-clip System consistently focuses on high-precision machines, state-of-the-art manufacturing technologies, and sustainable processes. In doing so, the company remains a driving force in the industry and plays an active role in shaping the industry's future. Visitors to IFFA 2025 can experience this transformation first-hand at the company’s booth. CEO Dr. Alexander Giehl emphasises: “Our transformation into a 'Packaging Company with less packaging' is a logical evolution, one that puts the diversity and benefits of our packaging solutions at the forefront. Today, our clip closure solutions meet the requirements for sustainable and efficient packaging more than ever: less packaging waste, lower CO₂ emissions in production, takes up less space during production and lower costs compared to conventional packaging solutions - true to the motto: less is more. At the same time, our core business remains sealing with clips and automation in all aspects of clipping. We continuously invest in research to expand our technological leadership and set sustainable standards for the packaging of tomorrow.’ CSO Mesut Akbulut adds: ‘We think in linewith our customers’ needs. IFFA 2025 is the perfect place for us to show how intelligent technology and sustainable thinking go hand in hand.’

[1] ManpowerGroup Germany (2025): ManpowerGroup labour market barometer for Q1/2025 - additional survey on skills shortages

Press contact

Poly-clip System GmbH & Co. KG

Niedeckerstraße 1

65795 Hattersheim a. M.

Deutschland