Less packaging, more sustainability

Under the motto “Just clip it”, Poly-clip System gets straight to the point: if you want to reduce material, conserve resources and produce in a more climate-friendly way, clip closure solutions are the way to go. A 2019 study[1] by the Fraunhofer Institute UMSICHT impressively demonstrates the advantages of clip closure technology. Compared to thermoformed packaging for sliced products, CO₂ emissions can be reduced by up to 81 per cent. In comparison with injection-moulded cups, the reduction is up to 64 per cent. Clip packaging also sets benchmarks in packaging efficiency: with a particularly resource-saving packaging-to-product ratio, it ranks among the most efficient solutions on the market[2]. In this way, clip closures make an active contribution to climate protection and support the industry in achieving its own sustainability goals.

Universally applicable

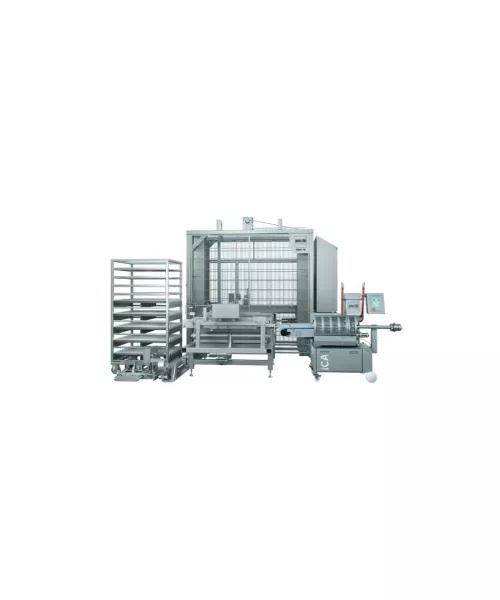

Poly-clip System’s clipping technology is universally applicable and used in both the food and various non-food segments. It impresses with high product protection, low material usage, and ease of handling. In the food sector, the technology is applied to a wide range of products: such as meat and poultry, soups, vegan products, as well as convenience items like ready meals. Sweet and baked goods, dairy products, and fruits and vegetables also benefit from tailored, hygienically safe packaging solutions with clip closures. Furthermore, the versatility of the technology extends beyond traditional food applications. In pet food production and the non-food sector – such as for chemical-technical pastes – clipping technology ensures efficient, safe, and sustainable packaging. In this way, it contributes to high-quality standards across various industries.

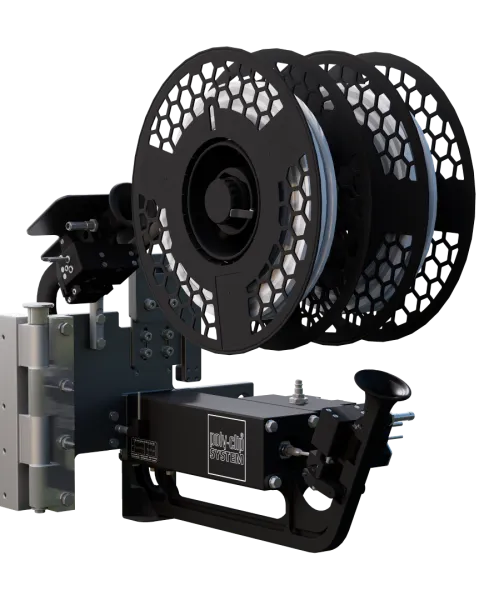

Net Clipper with Bio-Clip – Sustainability down to the last detail

The new Net Clipper CGC and Net Clipper Somi for fruit, vegetables and packaged sausages, developed in collaboration with Damarc Agrobotic, enable the use of biodegradable and industrially compostable Bio-Clips. Thanks to the innovative DC N3 600 clip head with 3D components, net packaging for fruit, vegetables, pre-packed sausages, and many other products can be closed securely and efficiently. The new Bio-Clips are made from a biopolymer-based plastic. They are biodegradable, made primarily from renewable raw materials, and are BPA-free. They are also food-safe (Fresenius-certified), industrially compostable, and available in various colours. In combination with bio-nets and bio-tags, this creates a cohesive overall concept for an environmentally friendly, future-proof packaging solution.

The Benefits of Clip Closure Solutions at a Glance

Poly-clip System offers more than just packaging – the global technology leader in clip closure systems provides simple, achievable solutions to current challenges with its packaging innovations. Clip closure solutions are hygienically safe, while also making the packaging process more efficient and cost-effective. They save storage space, reduce packaging waste, and lower CO2 emissions. Whether for traditional meat products, vegan meat alternatives, convenience foods, and more – Just clip it!

[1] Source: Study by the Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT on the calculation of the "Carbon Footprint" of packaging solutions for various sausage packaging formats (April 2019).

[2] Source: Study by Circular Analytics on the sustainability assessment of Poly-clip packaging and competing products (April 2025).

Press contact

Poly-clip System GmbH & Co. KG

Niedeckerstraße 1

65795 Hattersheim a. M.

Deutschland