Sausage & Meat

With our tried-and-tested and innovative clip closure solution clip-pak® we enable you to produce meat-based sausages economically and sustainably. Of course, we are also on hand to provide competent advice.

Excellence in Clipping

The demands on meat processing companies are high – and will probably increase even more in the future. In addition to the issues of hygiene and sustainability, this also concerns the increasing pressure to rationalise. For many decades, we have been helping you to master these challenges. And you will continue to be able to rely on our quality products, market-changing innovations and outstanding global service. That is our motivation and our promise. This is exactly what we mean when we talk about "Excellence in Clipping".

Innovative solutions

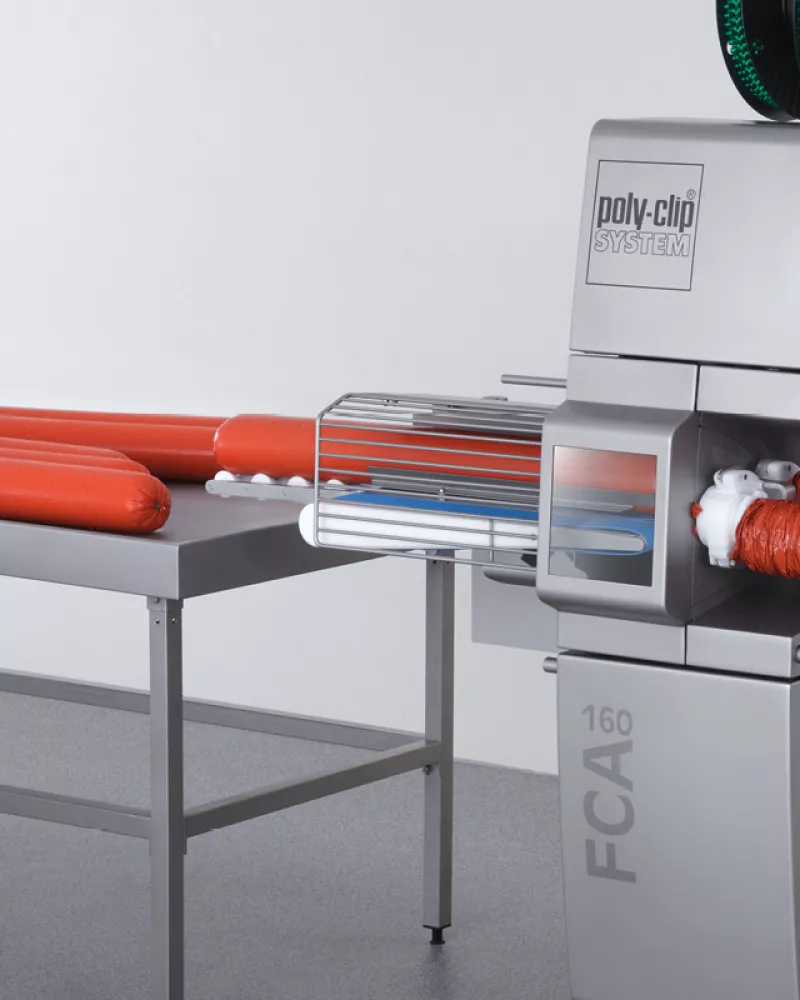

By the way, "everything from a single source" is not just a catchphrase to us, we truly live by it. We are at your side as process consultants and support you with a variety of innovative solutions that enable highly efficient, economical sausage production: from manual table machines and double clipping machines to automated systems for smoking trolley loading as well as consumables such as clips, loops and labels.

Individual clip closure solution

We are aware that "the sausage" has many sides. From sliced products, formed products or individual portion sausages to mini portions with tear-open aids, rings or hornlets, we will be happy to advise you on finding the right clip closure solution for your product. Through it all, you can always rely on our decades of experience in developing industry-proven packaging solutions with the clip.

CLIP-PAK - YOUR ADVANTAGES AT A GLANCE

The clip closure solution offers a multitude of advantages while being cost-effective and sustainable. At Poly-clip System we call this type of packaging clip-pak.

More sustainable than comparable packaging

The use of products packed in clip-pak® results in the minimum packaging material.This is helped by a 100% filling ratio and the use of relatively thin-layered flat films and casings. At the same time, this minimises the transport volume. As the product is shaped and packaged in one process step, subsequent processes and the associated ecological costs are saved.

Smaller carbon footprint

A crucial aspect of contemporary packaging solutions is their carbon footprint. clip-pak® impresses here with up to 81% less CO2 compared to other packaging solutions such as thermoformed packaging.

Economic investment in clip-pak® packaging solutions

The cost of a filling line for clip-pak® packaging solutions is comparatively much lower than investment for other forms of packaging.This is because clip-pak® packaging solutions allow the product to be shaped and packaged in a single process step – and do so cost-effectively and hygienically.