clip-pak® by Poly-clip System

clip-pak® clip-closure solutions: our innovative, economical and sustainable packaging solution for food, chemical products, pet food and more.

The innovative packaging solution

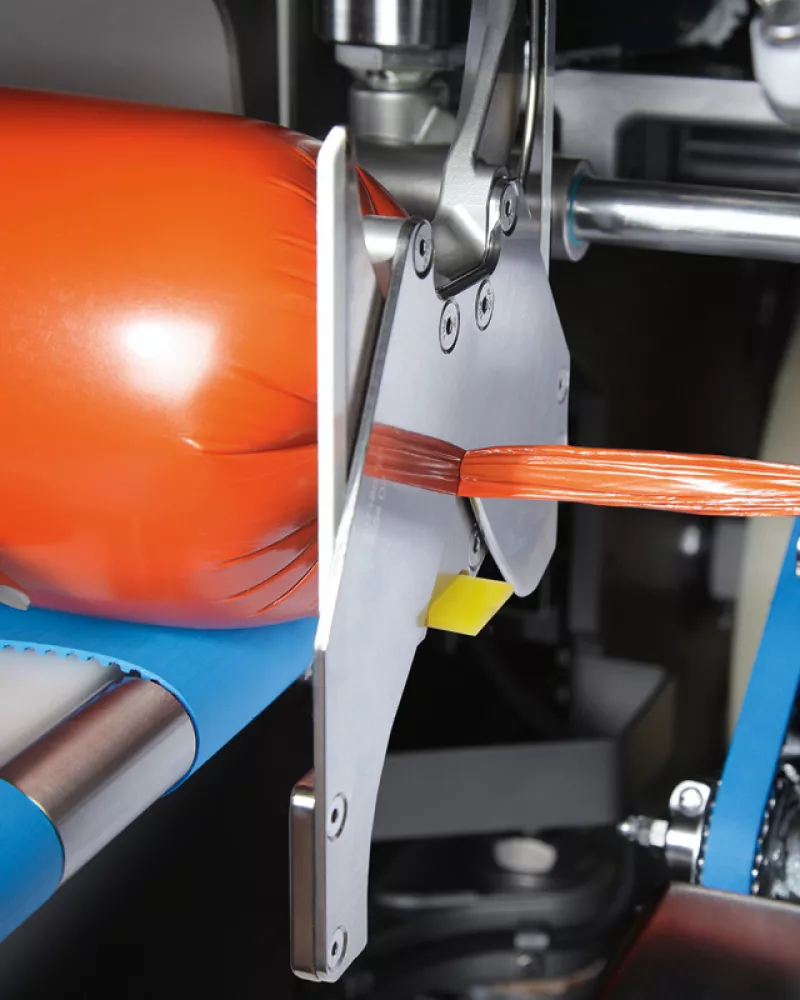

The great ideas are often the simplest: a clip-pak® is a tubular bag, which is closed at either end with a clip - essentially a sausage. The result is a safe and cost-effective packaging solution, which guarantees a tamper-evident closure by means of a clip. Depending on the product, it is possible, when using plastic casings or aluminium laminated film in conjunction with the R-ID Clip series, to ensure up to bacteria-proof closure with the clip. Packaging with the clip is space-saving and environmentally friendly; it achieves a high degree of emptying and leaves little packaging waste. In fact, packaging with less packaging material would scarcely be possible.

Packaging with the clip is space-saving and environmentally friendly; it achieves a high degree of emptying and leaves little packaging waste. In fact, packaging with less packaging material would scarcely be possible.

clip-pak®: the perfect packaging for various contents

All fluid, pasty to highly-viscous products can be packaged in a clip-pak® using a pump system with an automatic clipper. This naturally starts with sausage-based goods. However, clip-pak® is equally well-suited for herb butters, mozzarella, cheese, soups, marzipan, marinades, greases or Tofu products, and many other foodstuffs.

The innovative packaging solution even offers numerous advantages in chemical and technical industries. For instance, sealants, adhesives, lubricants and civil explosives can be effectively and safely packaged in clip-pak®. This makes the clip-pak® tubular bag packaging an effective alternative to traditional packaging (e.g. cartridges, cans, trays etc.).

All the advantages of clip-pak, at a glance

More affordable packaging alternative

In comparison to cans, trays or cartridges, the packaging costs for tubular bags are 30% less and packaging waste at the consumer end is reduced to a minimum. There is no large-scale warehousing or high shipping volumes as with empty cans, trays or cartridges, thanks to the space-saving film rolls and plastic casings.

More sustainable than comparable packaging

The use of products packed in clip-pak® keeps packaging material to a minimum.This is helped by a 100% filling ratio and the use of relatively thin-layered flat films and casings. At the same time, this minimises the transport volume. As the product is shaped and packaged in one process step, subsequent processes and the associated ecological costs are saved.

Smaller carbon footprint

A crucial aspect of contemporary packaging solutions is their carbon footprint. clip-pak® impresses here with up to 81% less CO2 generated, compared to other packaging solutions such as thermoformed packaging.

Long food shelf life

By means of pasteurisation in the packaging, whereby the product is filled cold as a clip-pak® and subsequently pasteurised, a shelf life of several weeks can be achieved with the packaging unopened, at a storage temperature of 7°C.

Longer shelf lives of up to 2 years, as achieved with tinned products, are also possible using the clip-pak® method, if you decide in favour of sterilisation in an aluminium foil.

Improved retention of the nutritional value of foods

In particular, products with added vegetables, such as soups and stews, benefit from the effective retention of nutritional value. This is because clip-pak® products are generally pasteurised at temperatures of up to 90°C, whereas tinned products are sterilised at 121°C. Essentially this means that they retain their nutritional value, their fresh flavour and their appetising appearance. This is made possible by the frequently used "Cook and Chill" procedure. Here the product is briefly heated to a temperature of around 90°C, is filled into the clip-pak® with as little temperature loss as possible, and then cooled as quickly as possible while in the packaging.

As such, clip-pak® packaging is in keeping with the "healthy diet" megatrend in multiple respects.

Economic investment in clip-pak® packaging solutions

The cost of a filling line for clip-pak® packaging solutions is comparatively much lower than the investment required for other forms of packaging.This is because clip-pak® packaging solutions allow the product to be shaped and packaged in a single process step – and do so cost-effectively and hygienically.

Versatile use of your clipping machines

The use of the clip-pak® packaging for other products gives you greater flexibility in terms of your machine utilisation. Especially if you have a small butcher's shop with machines and equipment already in place, you can use these to fill soups, sauces, and many other suitable foodstuffs, or even pet food. And this without the need for additional investment.

Most dishes, such as sausage products, can be filled using standard sausage fillers. For particularly delicate vegetables such as broccoli, cauliflower or Brussels sprouts, you can use piston pumps that avoid damageing the product. This way you guarantee that these products make it into the packaging in chunky pieces.