History

Our customers have trusted us since 1922 and have made Poly-clip System the world's largest provider of clip closure solutions. We are considered the global market and technology leader in this segment of the food industry and packaging sector, with more than 800 patents.

From 1922 until today

Our success story has a lot of history, always paired with product and solution innovations. Just right for your industry and your needs.

2022

We are celebrating 100 years of entrepreneurship: experience how adherence to a few core values has always kept our company young, even through extremely turbulent times.

2021

ICA with product form roller.

PCD 700/800 in family design – materials changed from aluminium to stainless steel and plastic and improved safety.

ES 6000 with new printer from own development.

2020

10,000 FCA clipping machines sold.

Opening of the new production plant for clips and loops in Gedern.

Poly-clip goes digital: Introduction of a web shop for machines.

Presentation of a new MPL: Stacking bag and chain bag in one control system.

Series introduction of FCHL.

Revision of SCA: Integration of safety brake, integration of two-hand start.

2019

According to Fraunhofer for Environmental, Safety, and Energy Technology, clip closure solutions for sausage packaging generate up to 81% less greenhouse gas emissions than thermoformed packaging and 64% less than injection-moulded cups.

Poly-clip goes digital: Automatic connection to the machine via QR code.

Poly-clip goes digital: Launch of the Mini Sales app & Lead app.

Poly-clip goes digital: Introduction of a web shop for spare parts.

Poly-clip goes paperless: Introduction of e-leaflets for IFFA 2019.

Presentation of a new FCHM hanging line in the form of a prototype at IFFA 2019.

New generation of machines without swivelling head.

Presentation of the new PDC-A 600/700/600 R with integrated safety casing brake and electric thread dispenser.

Semi-automatic Double-Clipper DC 600/DC 700: time-saving all-rounder with high performance by low purchase costs

"Clip in mould: In combination with the automatic double clippers ICA or FCA, moulded products are leveled and positioned in cooking moulds."

FCA 60, Automatic Double-Clipper: simply for small calibres, especially for snack products

FCA 160 and FCA 120, double-clippers with maximum automation for virtually unmanned production

2018

Poly-clip goes digital: Linking modern digital forms of learning and traditional face-to-face events.

Development of the FCHL 160 LS suspension line: Increased efficiency through combination with a robot-assisted smoke trolley loading system.

FCA 90 with new processor PC 200 and operating instructions on board; integration of the safety brake.

Automatic Double-Clipper ICA XL, for XL-calibre & value added casings

2017

Launch of the partner portal "My Poly-clip": Your Poly-clip knowledge is now directly available online.

2016

Introduction of the hygiene belt: reduced cleaning times and easy cleaning to prevent food contamination.

IFC interface between stuffer and clipping machine: 10% higher output thanks to intelligent communication.

FCHL 160, Automatic Clipping/Hanging Machine for efficiency increases of up to 25%

FCA 140/FCA 100 Automatic Double-Clipper: shortest downtime and fully hygienic conveyor belt

2015

FCA 90, air-free slack filling with up to 300 mm total spreading

Poly-clip System is DIN EN ISO 50001 certified – sustainability, energy management

2014

FCA 80 – the entrance into the FCA class

2013

Uniform PC control for the FCA series.

Electronic spare parts catalogue: quicker and more convenient to find the right spare part.

Traceability of R-clip: our clips can be traced back to the original material.

Excellence; BDA Architecture Award for our company building in Hattersheim.

DIN EN ISO 22000 certification for clip and loop production

2012

Innovative poultry packaging – automation makes its debut with the APL.

The clip-tube® is winner of the 2012 German Packaging Award.

2011

New company headquarters in Hattersheim a. M. (Frankfurt/Rhein-Main Metropolitan Region)

Market launch of the CBS Cap Bonding System and clip-tube®

2010

A world first: unattended smoke trolley loading with robot

Foundation of 2010 Poly-clip System to set up local production in the Russian Federation.

2008

ES 5000 with thermal transfer printer.

Quality certificate from SGS INSTITUT FRESENIUS: The Fresenius Institute certifies the food-safety of our clips & loops

TSCA 65 D with hydraulic dosing pump HDP for chemical/technical products

2007

Introduction of the:

- Linear displacer

- Fully automatic casing suspension

- Clip pressure monitoring

- Central lubrication system

- Quick cavity change

- Titanium lever in FCA

ICA SL is created as a solution for heavy products in the fibrous casing.

The FCA 50 is the fastest clipping machine in the world (300 sausages per minute).

New generation of FCAs is presented: FCA 160, FCA 120 and FCA 50.

New clip generation for maximum automation: the R-ID Clip for tight sausage closure, up to bacteria-proof, processed by the fully automatic FCA 160

85th company anniversary and 50 years of R-Clip (reel clip)

2006

Plastic clip establishes itself in the market.

First suspension line AHL 1000 coupled with an FCA 3430-18 brings PROMAR the "Golden Polagra" and two other medals.

SAFE-COAT Clip: the first patented clip with safety coating.

2005

Easy-Touch touchscreen for simplified operation of the machines is installed for the first time.

2004

Clip end detection for FCAs.

FCA 3430-18: the fastest universal clipping machine in the world

2003

Two-in-one: clipping and sealing with the TSCA 65

clip-pak closure establishes itself in the non-food market.

2001

Introduction of the PDC-A, the solution for less compressed air consumption.

ICA 8700 with revolutionary iris separator – large calibres at record speed!

2000

No-residue loop.

1998

The professional clipper for small and medium-sized operations, the PDC 600/700, begins its highly successful advance.

1997

Poly-clip goes digital: www.polyclip.com goes online.

Poly-clip System is certified according to DIN EN ISO 9001 for the first time.

75th company anniversary

1996

Launch of the Easy Clip Line®, specially developed for packaging poultry in bags

1993

Production of the 1,000th Automatic Double-Clipper FCA 3415.

1992

First high impact polystyrene, one piece injection moulded, fully recyclable coil.

Reel container system: Clip reels are brought to the customer without any packaging.

1991

Poly-clip System is adopted as the uniform brand name in the market. The family name Niedecker recedes into the background in favor of the product name.

Poly-clip System sales exceed 100 million DM.

1990

Frank Niedecker joins the family business.

1988

The TSA is being used for the first time for the application area of sealants for construction, installation and sanitary engineering: Start of large-scale replacement of plastic cartridges with clip-pak®.

1986

Cooked ham can be filled and clipped automatically thanks to overspreading.

First double-clipper FCA with pneumatic casing brake

1983

The first TSA and TCA will be presented at IFFA 83.

1981

Poly-clip sales exceed 50 million DM.

The first Automatic Sealing Machine TSA is built.

1978

Manufacture of the 1,000th Automatic Double-Clipper FCA 3401.

1977

Internationalisation of the brand: Poly-clip System in the USA (formerly US-Clip Corporation) is founded to set up local production.

1975

Automatic Double-Clipper FCA-SUPER 3451 with voiding separator is patented.

Automatic looper GSA and labyrinth clip are patented.

1973

The Automatic casing brake is developed.

1972

Registered trade mark "poly-clip" is announced worldwide.

Development of the first loop knotter, which replaces loop production by homeworkers.

1971

Internationalisation of the brand: founding of Poly-clip System Ltda. in Brazil.

1970

For reasons of capacity, the production of clips is moved to Gedern.

1967

The Filling-Clipping Machine FCA 3401, with reel clips, allows the automatic production of portion sausages for the first time.

First Poly-clip activities in the Russian Federation

1966

Development of the S-Clip with rhomboid cross-section.

1962

First participation in the IFFA exhibition in Munich.

1959

Founding of Niedecker Verschlußtechnik GmbH (NVT), the parent company of the current Poly-clip System, which brings together all the activities associated with sausage production.

1958

The first voiding separator for the DCE Double-Clipper is patented. This development revolutionises sausage production worldwide and leads to humanisation of the workplace in the meat processing industry.

The trade mark "poly-clip" is registered.

1957

Invention of the reel clip (clips on reels, patented)

Closure with a clip meant a humanisation of the working world, as the previous tying did not proceed without damage to health.

The idea of closing sausages with metal clips is conceived during an exchange at an exhibition.

1952

On 01.03.1952 Herbert Niedecker takes charge of the company and its 50 employees.

1950

Complex punched and formed parts, mainly brake parts for the automotive industry, are manufactured.

1948

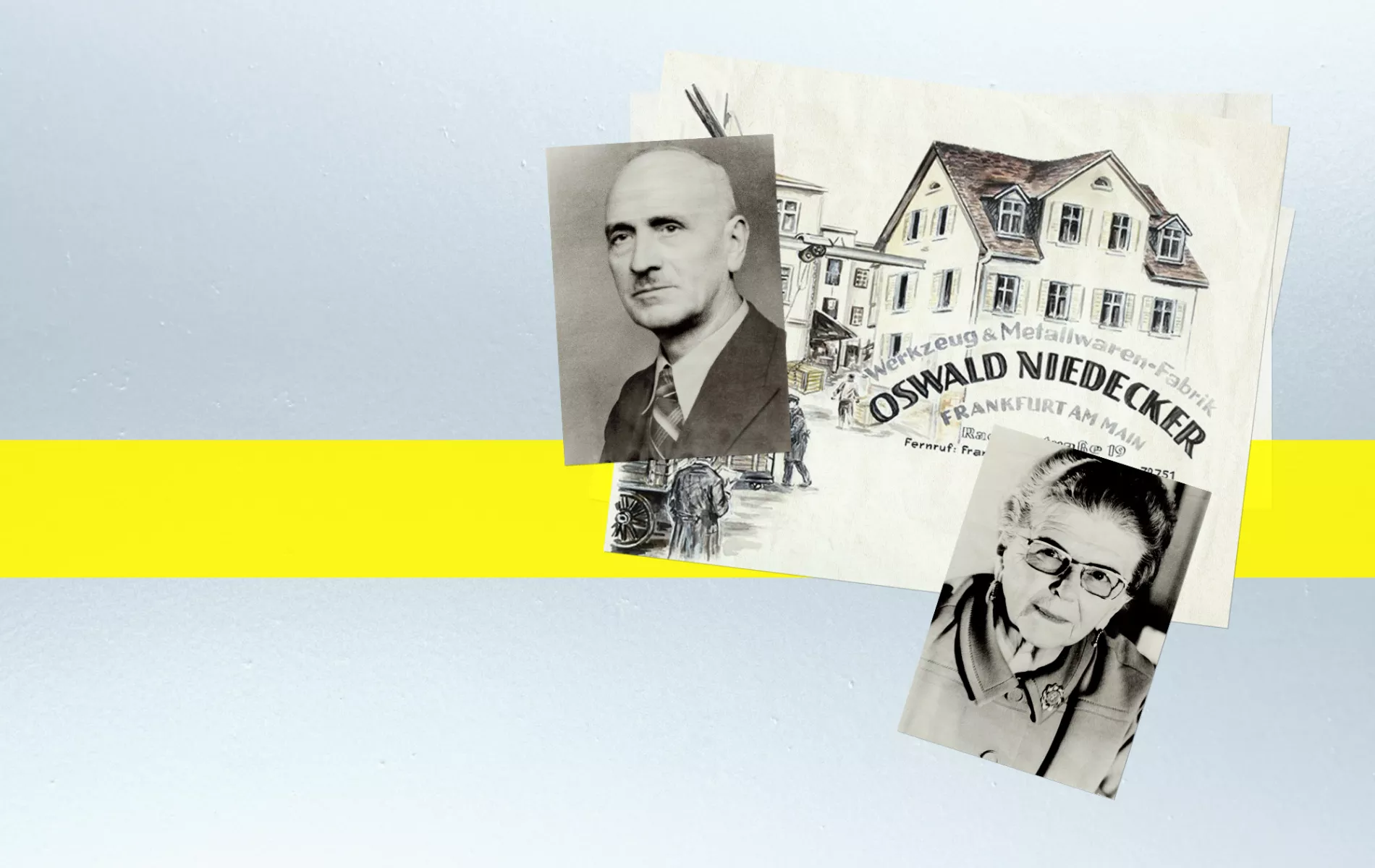

After the death of her husband, Oswald, Elisabeth Niedecker takes over running of the company until 1952.

1932

The company Niedecker is one of the most successful lead seal manufacturers in Germany.

1922

Founding of Oswald Niedecker Metallwarenfabrik oHG on 1st March 1922, producing tools for sheet metal working and forming.

Company founders: Elisabeth and Oswald Niedecker