Technical & Non-Food

The highly productive, established and sustainable clip closure solution clip-pak® is suitable for numerous sectors outside the food industry: chemical and pharmaceutical applications, pet food, tobacco or even hygiene products – in fact almost anything that is liquid to highly viscous.

Sealants & Adhesives

When filling and packaging high-viscosity products such as sealants and adhesives, the cohesion (shear strength or separability) and the adhesion (capacity for sticking to other products) also play an important role.

Poly-clip System has a wealth of experience in this area and already has several hundred of its machines in daily use.

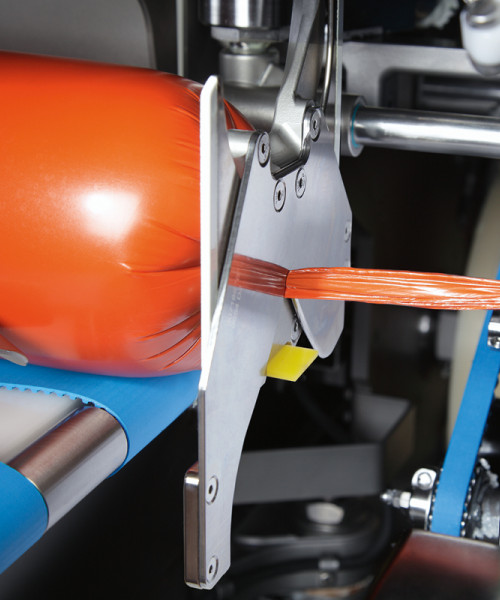

Our tailor-made solution for sealants and adhesives is the TSCA 65 D.

Explosives

For many years now Poly-clip System machines have been employed in the packaging of explosives in large-, medium- and small-calibre packages.

The challenges of packaging these products are quite varied: the viscosity of civil explosives ranges from liquid to paste-like when filling.The filling temperature lie between 40 and 90°C. Typically the product calibre is between 25 and 120 mm, for portion weights of 200 to 1500 g. In addition, packaging should be done with as few interruptions as possible. Where more protracted interruptions occur, the composition and/or density of the resulting explosive may change, which could lead to a different blasting outcome.

Our tailor-made solution for explosives is the TSCA 120/160 and the clip-pak® packaging we introduced in the explosives sector.

Pet food

When it comes to pet food, a basic distinction is made between wet feed and dry feed (also "treats"). The latter is often packed in bags. Bag clippers are ideal for dry, lumpy products.

But especially wet dog food, in individual cases also cat food, can be ideally packaged as wet food in clip-pak® (sausage shape).

Fresh food (BARF)

Fresh meat is packaged in clip-pak® and treated as fresh produce. The pet owner obtains a hygienically packaged product which can be fed to the pet as a raw product or cooked along with additives such as rice and then served. The purchasers of such products are essentially commercial breeders, who buy the clip-pak® products in large containers weighing 2-5 kg. The shelf life is a maximum of one week stored at temperatures of 4-8°C.

The dosages of pet food in clip-pak® (dog sausage) vary and are adapted to the individual needs of pet owners.

Frozen products

Besides fresh feed, the frozen feed market is becoming bigger and more important. Ultimately, a longer shelf life of up to six months is possible when products are frozen. For container sizes of 2-5 kg. The clip-pak® packaging process is perfect for this.

Pasteurised products

Many pet owners buy ready-made food that is already enriched with additives such as rice, fish, chicken, vitamins, etc. These products are often pasteurised.

The best and most cost-effective form of packaging for this? Our clip-pak® process. Exclusively filled in plastic bags, our process allows the feed to be kept for 6-8 weeks with appropriate refrigeration. And that in packaging sizes between 200 g and 1 kg.

Sterilised products

These products are a genuine alternative to finished products in cans and trays.

Our clip-pak® process is also suitable for this requirement: Sterilisation in a counter-pressure autoclave at a core temperature of 121°C achieves the product status of a fully canned product. With lower costs and better overall packaging sustainability.

The packaging material must be aluminium laminated film, as the water vapour barrier provided by plastic films is not sufficient to maintain a constant product weight over such a long period of time. Packages are produced in units of 200 g to 1 kg, and in special cases also 80 g, as dog snacks.