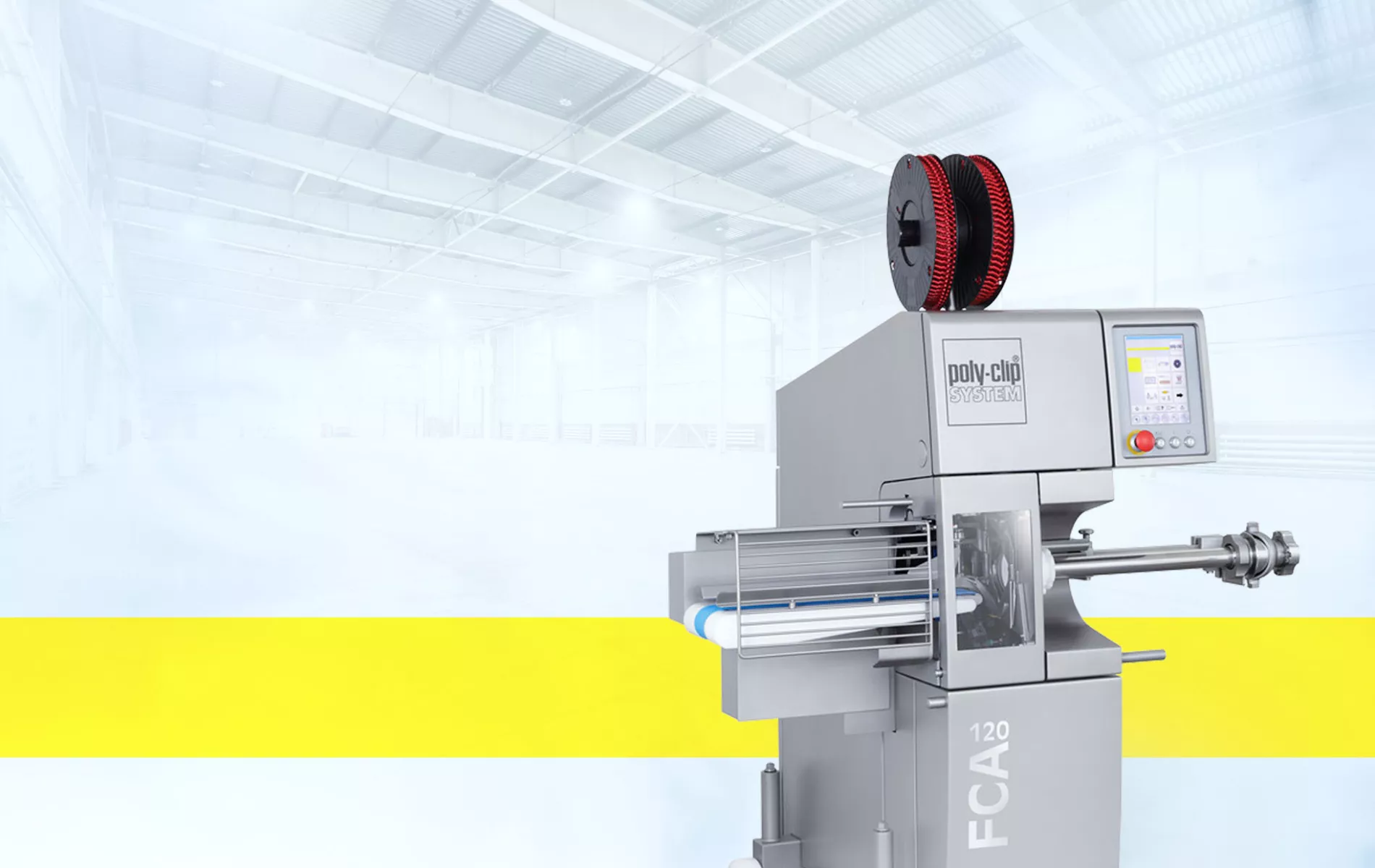

Today, clipping is a natural and core component of all industrial sausage production.

And for small and medium-sized operations, too, the clipping machine has become part of the armoury of important production tools which considerably lightens the workload and saves time, as it replaces the labour-intensive tying procedure. But it is not as run-of-the-mill as it sounds. It is of course the form of a clip closure that is always demanded for a casing or tubular bag, but the requirements placed upon this closure are extremely varied.

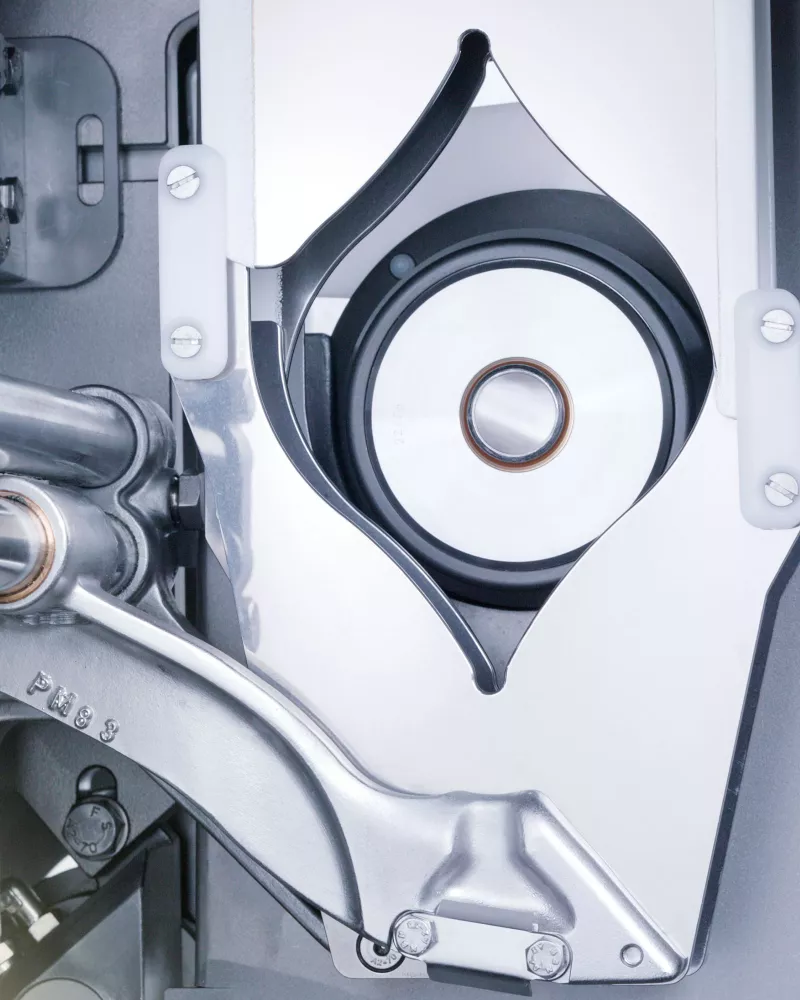

Clip closure is subject to a range of conflicting requirements. It must, for example, close casings and tubular bags of differing thickness, sensitivity and hardness, and must do so gently, but also powerfully. Pre-tied casings with widely differing filling capacity must be closed just as securely as products which are divided into portions of precise weight. Production speeds up to 300 portions per minute are possible, depending on the filling weight, product viscosity and package calibre (diameter). In addition, there are a variety of product forms involved, such as portioned sausages (chubs), rounds, half rounds and bladders.

Additionally, the clip closure must withstand the high filling pressure, and it must be tight, but also flexible where necessary. Clip closure must be dimensionally stable even above 80 °C, since the product is sometimes subjected to further thermal treatment, as in the case of cheese which is smoked. It must be capable of closing both hot- and cold-filled products. Thus, clipping technology is more demanding than it might at first seem.